It is important for us to keep in mind a feature-oriented solution from the beginning when choosing hardware and software components.

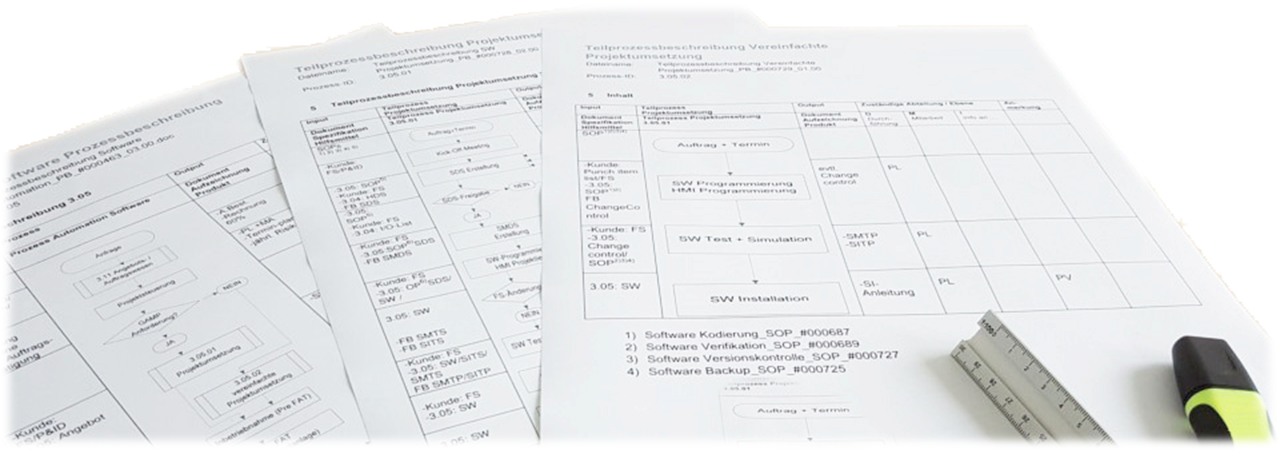

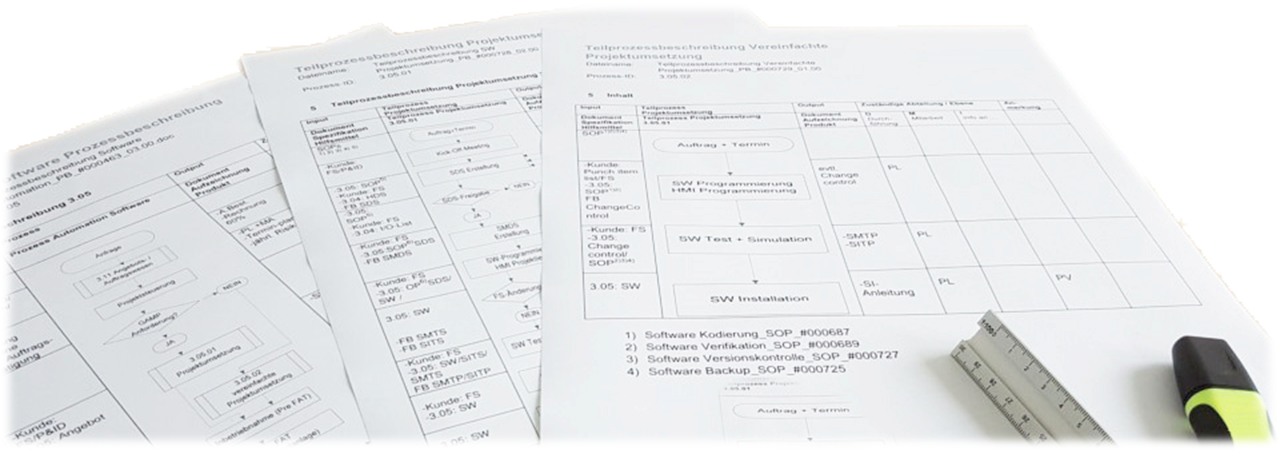

The success of each project begins with planning, and we have worked closely with you to analyze all the requirements of the automated process before embarking on a collaborative project. In addition to possible compatibility with the control systems established by your company, at this stage, we also note the following PLC programming requirements. During the course of the project, we will provide you with all the necessary specifications for economic and modern automation concepts. We followed the GAMP5(good automated manufacturing practices) guidelines to support our industry customers in validating their system layouts.

In the debugging phase, careful and comprehensive planning is also important to us. Well-thought-out planning can facilitate the maintenance options we provide for our systems throughout the life cycle: years after delivery, we can still make software and hardware changes efficiently and quickly.

During the project with your company, we work hand in hand with your company and internal project participants.

All business units involved are aware of the compatibility of the hardware and software used and the user-friendly user interface.

Dawson's advantage

Intensive customer service

Develop concepts according to customer requirements

Comply with all applicable standards and legal guidelines

Documents (for example, according to Gamp5)

Circuit diagram, parts list and wiring diagram

Project visualization

Long-term filing of all project documents

Modernization and restoration of old projects

Develop personalized solutions

Contant DOWESTON

DOWESTON® is a premium instrumentation and sensor brand serving customers worldwide.

DOWESTON® is dedicated to bringing users a reliable, easy-to-use, efficient and advanced

inspection and measurement experience.

Not seeing a product that suits your needs?

Let DOWESTON sales engineers make the selection for you