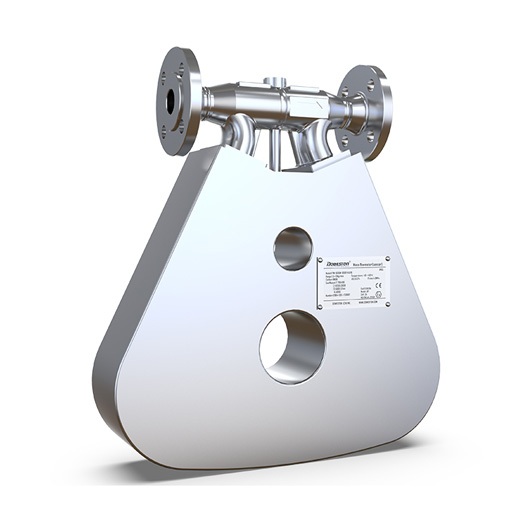

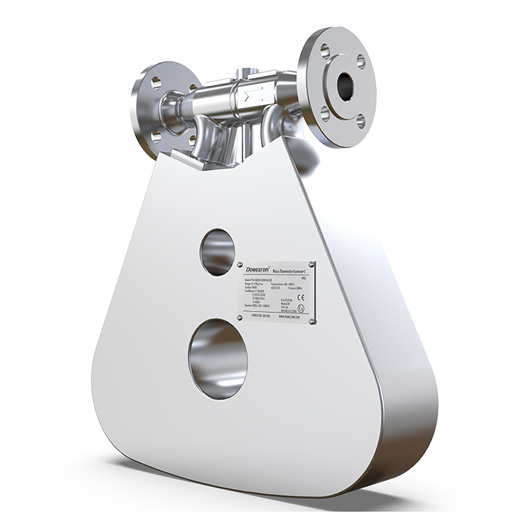

The FTM-LNGmass series mass flowmeter uses Coriolis effect effect to directly measure the mass flow of the medium passing through the flowmeter, and on this basis, it is specially designed and developed for the LNG filling machine, it can be used to measure the mass flow rate, volume flow rate, density and so on. It is suitable for injection, transfer, storage control and so on.

Reliable measurements can also be made in extreme environments

Integrated process measurement equipment-(flow, density, temperature) multivariable measurement

Save space required for installation-no straight pipe length requirements before and after installation

Design of compact structure: small space to achieve all the functions.

Quick debugging: pre-configuring equipment.

Automatic recovery of data for ease of service

Scents the principle of Gaspard-Gustave de Coriolis mass flow measurement is not affected by the physical properties of the fluid itself, such as viscosity and density.

Precise metering of cryogenic liquefied natural gas in liquefied natural gas (LNG) dispensers.

The flow rate can reach 18000 kg/h (660 lb/min)

The medium temperature may be as low as -196 ° C (-321 ° F)

Nominal diameter: DN 8 to 25(3/8 to 1”)

A rugged and wear-resistant compact transmitter housing.

Modbus RS485

Design to meet application needs